The characteristics of the radio-controlled self-propelled tool carrier Herbhy

The engines of the radio-controlled self-propelled tool carrier Herbhy

Hymach offers radio-controlled machines with diesel and petrol engines.

Herbhy is equipped with an industrial Perkins diesel engine. Compact, very robust and reliable over time, it uses horse power without stress and overheating. The entire powering system has been designed and tested to work continuously even in slopes up to 55° and ensure consistently high productivity.

An excellent engine/power torque for an efficient and effective work in normal operating conditions, with no effort.

The fuel tank is made of stainless steel to maintain maximum efficiency of the fuel system. The system works under optimum temperature conditions thanks to the cooling system’s reliance on the robust and reliable Flexxaire fan, with bidirectional rotation, we tested in extreme environments.

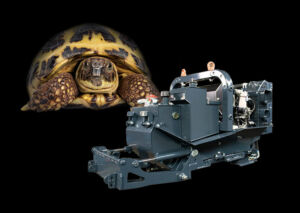

Underbody protections of the radio-controlled self-propelled tool carrier Herbhy

The compact underbody coating is structurally integrated into the chassis and prevents access of debris and fragments, effectively working as a “shell” protecting engine and all system parts.

The roll-bar too is framed within the chassis and can be used to lift the vehicle in complete balance. The frame also features a more point hooking structure to lift the vehicle, as well as front and rear hooking systems for the fastening of equipment and optional devices. High-visibility LED headlights and blinkers.

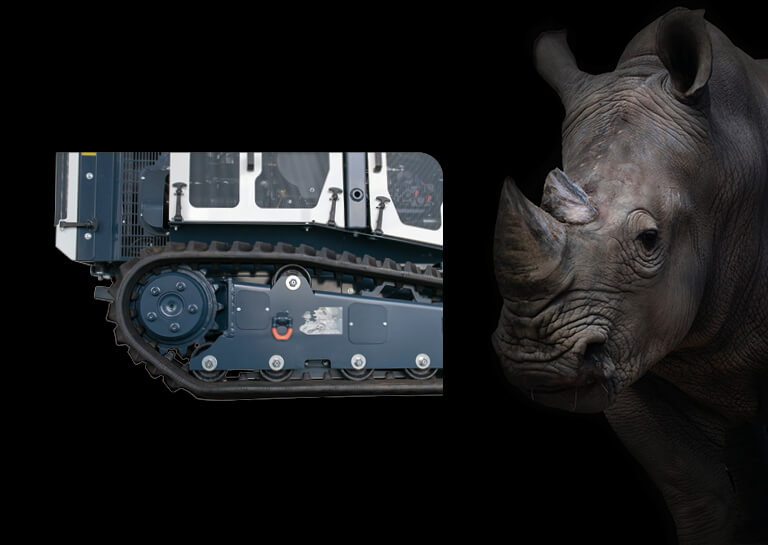

The tracked undercarriage of the radio-controlled self-propelled Herbhy

The tracks are slip-resistant and feature an automatic hydraulic tensioning system that helps to dramatically reduce the possibility of leakage, and increase security and productivity.

We propose different types of tracks: high-adhesion rubber for mixed terrain, and tracks with steel inserts to which studs can be added for work on extreme slopes.

Work safely on slopes with Herbhy radio-controlled machines

Operation via remote control and the ability to work safely both on flat surfaces and slopes make HERBHY particularly suitable for use in hilly and mountainous areas, dikes, embankments and highways, areas adjacent to railway lines, military zones, industrial and energy plants, as well as state-owned forest areas, alpine woods, in the presence of fire, in airports, land reclamation districts, provincial and municipal areas, and sports facilities.

On the side of the environment with the Herbhy radio-controlled multi-purpose self-propelled vehicle

Herbhy LE series with new Perkins engines, which meets the EU STAGE 5 emissions standards, offers more power with reduced fuel consumption. In HERBHY the plastic parts are reduced to the least amount possible. The body is made of steel, a material that is 100% recyclable over and over again, resistant even in the most demanding jobs such as trailblazer and deforestation.

Always in an eco-friendly spirit, the hydraulic system is compatible with the use of biodegradable ecological oil and has been optimized to increase the working time interval between maintenance services with consequent savings on consumables.

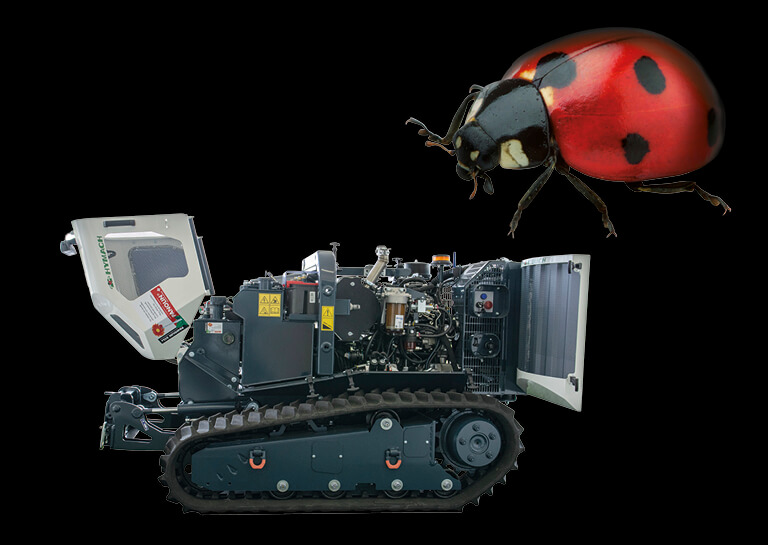

The track width is variable in Herbhy radio-controlled tool carrier

Herbhy is equipped with an extendable carriage, with independent widening of each track, to better deal with the type of territory it may encounter.

The machine with widened carriage manages to be more efficient on slopes, especially extreme or non-homogeneous ones, and more agile when it encounters obstacles. The increased stability is also useful when particularly large equipment is installed.

The remote control system of Herbhy self-propelled tool carrier

The radio control, equipped with graphic display, oversees all vehicle functions. The vehicle features a track speed control system with a 0-7 km/h fore and aft adjustment and a reporting system for the notification of critical events while the machine is in operation, including the overcoming of slopes.

It also features a standard speed control potentiometer with variable feed

from 0 to 100%, the potentiometer for the correction of the forward direction during work in slopes and the assisted maintenance application (service assistant).

Customizations and fittings for Herbhy radio-controlled tool carrier

Several optional accessory set-ups make Herbhy suitable for the needs of each user: the multi-connection unit for hydraulic connections, the body protection frame (with winch included) for work in situations with a high risk of collisions, the horizontal translation system for the equipment applied, the winch, the vision system with camera, customized colorings, design of variants on request for specific uses, the interconnection system which, in addition to allowing the exchange of data for remote management and monitoring of the machine, makes it suitable, in Italy, to fall within the assets where aid is available within the 4.0 national transition plan.